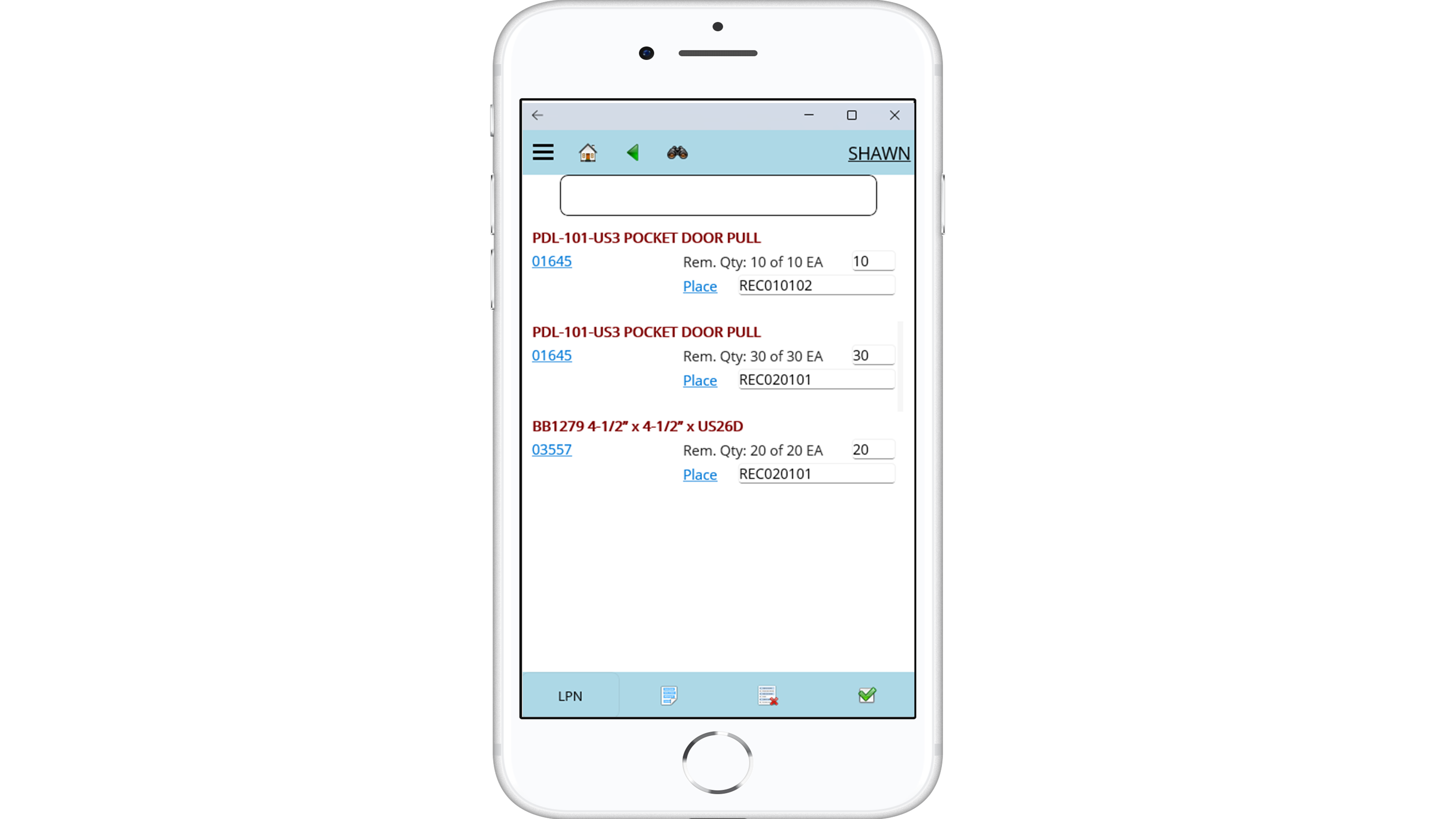

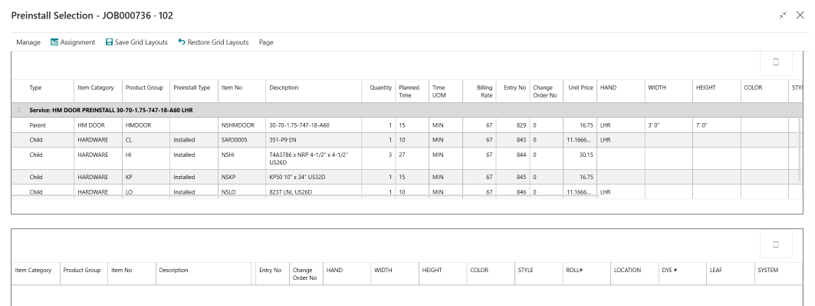

Pre-Installed Material Services

contractERP’s Pre-Installed Material module enhances production efficiency by allowing you to manage value-added services such as: painting, installation of hardware on doors. ensuring that items are prepared and ready for installation or shipment.

- Customizable settings: Set up services and define work by product group, allowing for precise control over how materials are prepared and delivered.

- Flexible material handling: Choose whether materials are shipped as a combined unit, loose with the main unit, or independently ensuring that all components are ready for quick and efficient assembly or installation on-site.

- Optimized setup and cost management: Assign planned installation times and costs by product group, enabling better resource planning and accurate costing for pre-installed materials.

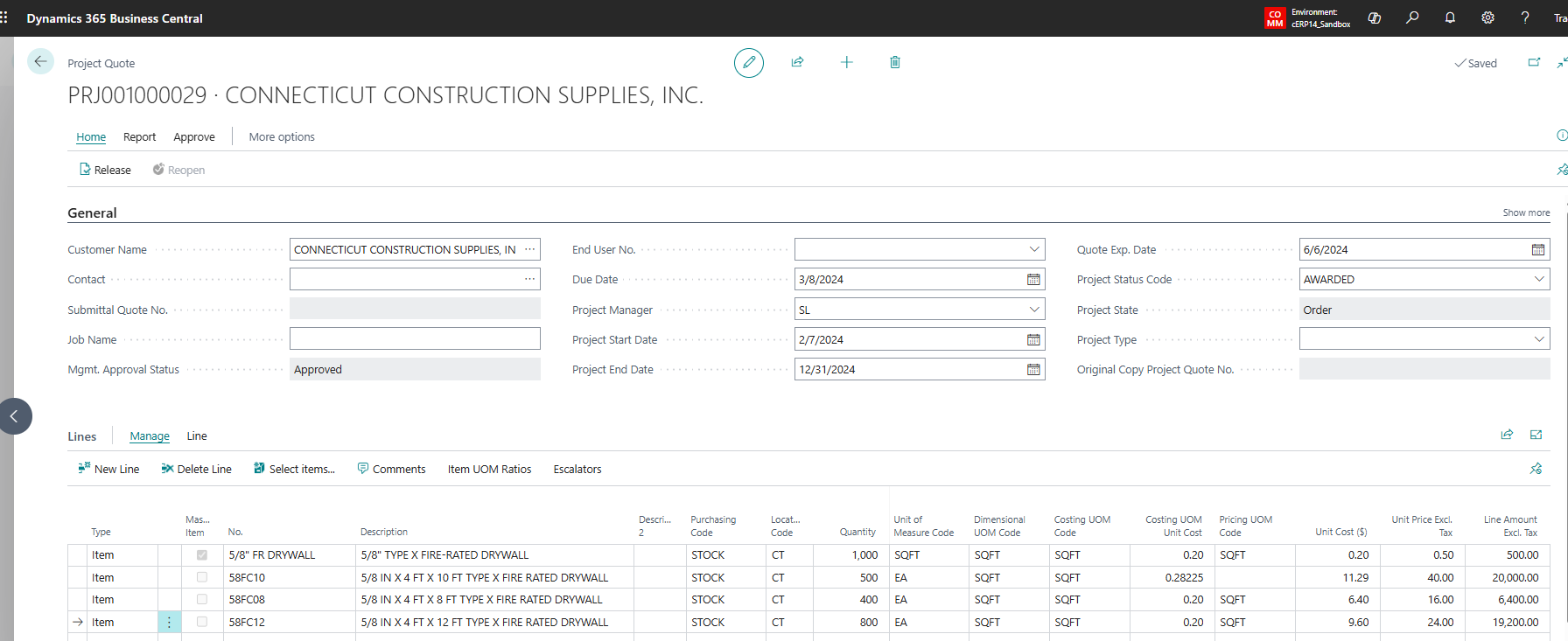

Building Materials

Simplify project-based quoting and fulfillment for building materials with flexible bulk estimates and phased releases. Easily manage both square footage and dimensional materials, tracking consumption against the original quote to stay accurate and on schedule.

- Quote smarter: Accurately estimate total project requirements, including bulk and dimensional materials (square footage, linear footage, board feet, bundles, and more) right from the start.

- Variable material fulfillment: Release materials in quantity and dimension as the customer requests them.

- Track with confidence: Monitor all orders and shipments against the original quote to ensure accurate price breaks and complete fulfillment.

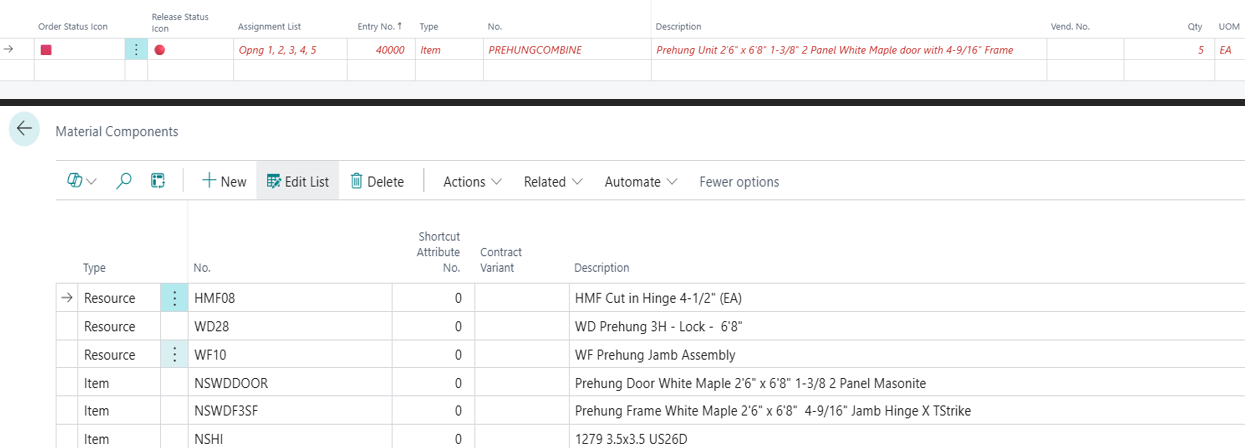

Pre-Hung Door

Designed to address the operational needs of managing the complexities of pre-hung door. This solution allows for combining components into one finished good while maintaining the visibility of tracking of each individual part.

- Make vs buy: Leverage inventory stock levels to determine at the unit or the component level if you will make or buy to create the finished good.

- Data flexibility: Import, absorb and combine into one line item regardless of the detailing integration.

- Reliable cost: Easily calculate and track costs for materials, fabrication, and installation, ensuring your orders are competitive without sacrificing margins.

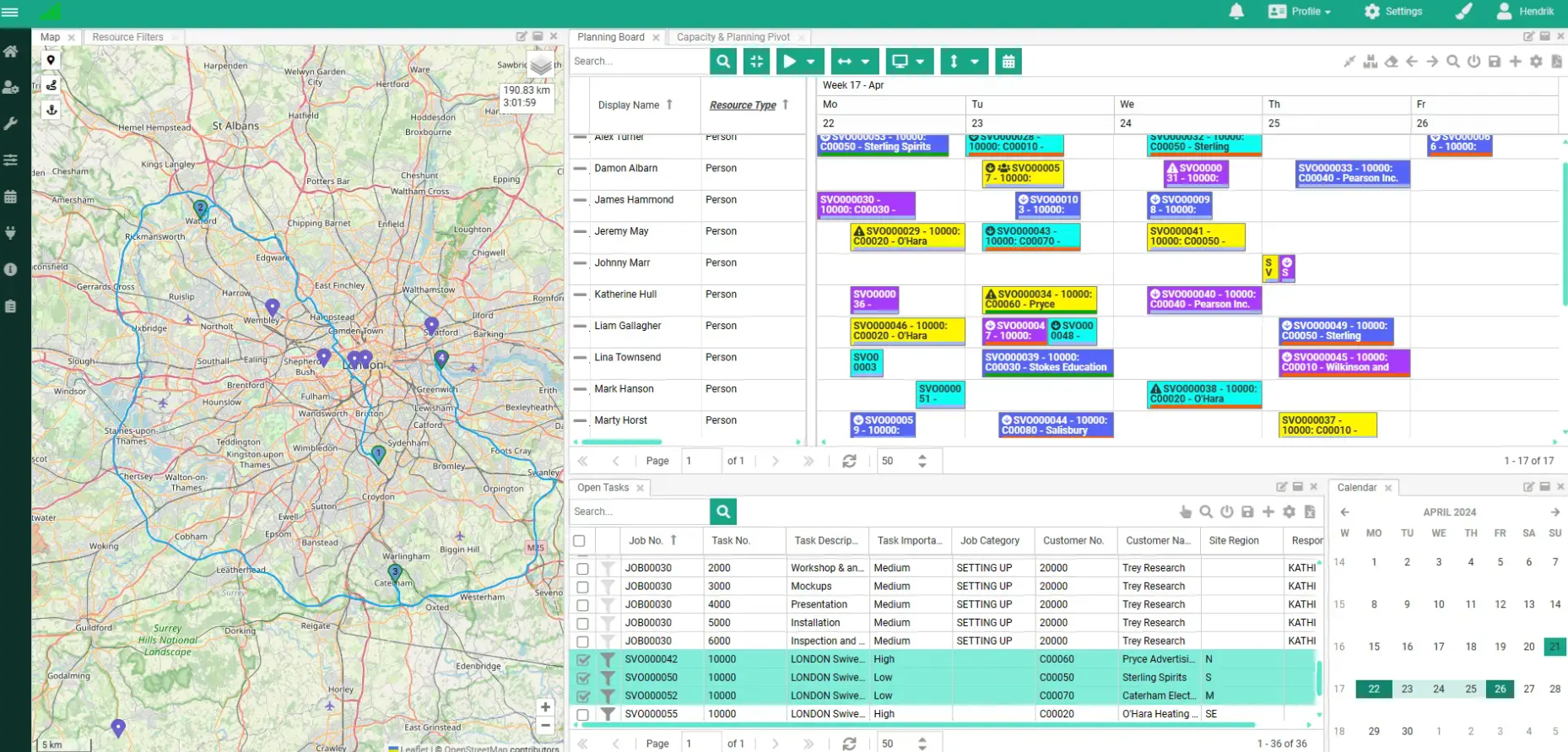

Resource Scheduling Board

contractERP’s Resource Scheduling Board boosts customer satisfaction and labor efficiency by helping you maximize the use of technicians, equipment, or other field resources. Pairs seamlessly with contractERP work orders or Field Service Management module for end-to-end operational control.

- Smart scheduling: Track planned, scheduled, and remaining time to assign techs or equipment with easy drag and drop tools.

- Map-powered efficiency: Visualize routes and assign multiple jobs per tech to reduce travel and maximize productivity.

- Flexible views: Customize your schedule layout to match your workflow and manage resources your way.